CSR・CSV

Ginza×CSR・CSV Vol.12 Ginza Tanagokoro

The world’s first dedicated binchotan charcoal shop

Supporting forest restoration for the future through the Donguri Project

2014.04.18

For the 12th part of the Ginza×CSR series, we interviewed Masayo Kurata of Ginza Tanagokoro, the world’s first binchotan (high grade charcoal produced from certain trees such as ubame oak) shop. Ginza Tanagokoro, in its 15th year, is filled with art pieces and accessories that exude the unique radiance of Kishu binchotan. We asked about the strong points of binchotan as a “gift from the forest” and the Donguri (Acorn) Project to support forest restoration together with customers.

Binchotan creation that harnesses the qualities of raw timber

- ─ All the binchotan art pieces and accessories in the shop have a calming shine and exude an elegant aura.

- In high quality binchotan, the cut surface shines like black diamonds and it rings with a metallic sound when struck. When people think of binchotan, they often think of the fuel that is used in barbecuing, for example, but what we do is process high quality binchotan to develop products that harness its unique qualities to give our customers added value.

We do not waste any parts of the timber, for example making thin branches into stir sticks or using small fragments as beads. - ─ So, you fully utilize the qualities of raw timber that is a blessing from the forest. Where is it the production area?

- It’s Minabe, a town in Wakayama prefecture that is the most historical place for producing binchotan. For over a thousand years, ubame oak and Japanese blue oak have been carefully nurtured and made into charcoal there.

The Minabe River Forest Cooperative, to which we are indebted, fells logs for us. They care for the forests through thinning and mowing the undergrowth to let the good trees continue to grow, so they know the mountain very well. That is why we chose this location for production.

Image of binchotan

Future forest development through dialogue with charcoal makers

- ─ Do you visit Minabe often?

- All of our staff, including myself, visit the production site for training. Aside from training, we also visit the site often to talk with the charcoal makers about the condition of the mountain and the future of the forests.

The charcoal makers usually deal with suppliers that purchase the charcoal for use as fuel, so they are uplifted by our understanding of the excellent finish of the charcoal from a different perspective and by how we develop products from the binchotan they made to be used as aesthetic and decorative pieces for Ginza. - ─ How do you utilize your exchanges with the charcoal makers?

- Our relationship with them involves more than simple transactions of going to purchase finished binchotan; we try to reflect background properties, such as the state of the Satoyama (forests near settlements) and the sentiment of the makers, in product plans.

We create binchotan while taking good care of the Satoyama with the charcoal makers, based on the idea of developing the environment for future generations. We are delighted if our business is an opportunity to raise awareness for a rich environment in the future among our customers.

Photo of charcoal making

Restoring forests together with customers

- ─ The Satoyama, the charcoal makers, the staff at Tanagokoro, the products, and finally the customers are all connected by a line formed from a unified sentiment. I heard that you also carry out tree planting activities with customers.

- We started a tree planting project six years ago. There were once plans to construct a race circuit in the Minabe mountain forest zone. They began large-scale development construction work that would cut through the forest, but the plans were aborted. Minabe bought back the mountain that was deserted, and began planting trees to develop the Minabe 100 Year Forest.

Then, we decided we wanted to help restore the forest, and launched the Donguri (Acorn) Project as an activity to plant seedlings raised from acorns together with customers. Several times a year, we hand out acorns to customers who visit the shop. We then take the saplings nurtured by customers with their heart and soul and plant them in the Minabe forest. - ─ Perhaps it is precisely because your customers recognize the blessings of the forest through binchotan that they sympathize with the project.

- When planting the trees, we mix used up binchotan with the earth. The quality of the water running upstream is improved, so this helps conserve ocean ecosystems. Remembering that the oceans and rivers are all connected makes us want to take care of the forests to preserve the environment.

Giving back the nature we borrowed to the future

- ─ Without human assistance, forests become wild and fall to ruin. Is it right that binchotan production is linked to caring for the forests?

- The raw timber used to make binchotan is about 30 years old. We are borrowing nature from the past, so we want future generations to inherit rich forests. Rich nature remaining in one’s birthplace and having an industry you are proud of that has continued for many years becomes a spiritual anchor when you grow up. Perhaps this is what develops human character.

- ─ There are still places where a strong demand leads to logging more trees than the proper amount that can be supplied.

-

An experienced charcoal maker said that, “Good charcoal is made not by good charcoal firing techniques, but by good mountain nurturing techniques.”

The Minabe River Forest Cooperative also trains charcoal makers to convey the importance of nurturing the mountains. We also sometimes go to help out with training.

An important point of the Donguri Project is not simply how many trees we plants, but conveying to customers the importance of nurturing the forest and the sentiment involved in continuing our relationship with the local production area. - ─ What is the response of customers who visit the Ginza shop?

- For example, they understand that organic cotton products protect the health of the producers. Meeting customers with such a high consciousness is a strong attraction of doing business in Ginza. I hope to continue developing a shop that is valuable and loved, centered on cultural activities.

Raw timber for binchotan

- Visit the following website for more information.

- Ginza Tanagokoro

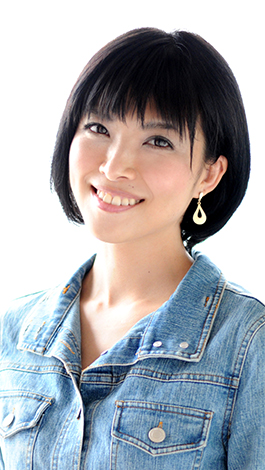

General Manager of Ginza Tanagokoro

Masayo Kurata

After working as the secretary for an automobile importing company and in the public relations office in the restaurant industry, joined the company in 2006 as the manager of the Ginza Kishu Binchotan Shop Tanagokoro. In 2008, was made general manager of three branches and assisted in launching the tea room and bar. At the same time, obtained qualifications as a environmental health translator to provide customers with ideas for high quality living. Ginza holds many memories for her of riding the Toden streetcars during her youth and enjoying food and shopping. She also strives to convey the great points about working in Ginza to the younger staff.

Interviewer:

Karin Sugiyama

Alterna consultant Offered services in marketing, communication, business strategy and new business development activities for foreign-affiliated IT companies, advertising agencies, and public relations firms. After going independent in 2008, Sugiyama now participates in educational projects for solving social challenges, assists cooperative alliances between companies and NPOs, and offers consulting for CSR activities and practical assistance.

Writer: Karin Sugiyama Planning/editing: Alterna

All List

- Ginza×CSR・CSV Vol.39 Oris Japan

- Ginza×CSR・CSV Vol.38 MOTHERHOUSE

- Ginza×CSR・CSV Vol.37 CITIZEN

- Ginza×CSR・CSV Vol.36 LOFT Ginza

- Ginza×CSR・CSV Vol.35 Ginza Natsuno

- Ginza×CSR・CSV Vol.34 Yamano Music

- Ginza×CSR・CSV Vol.33 BRITA Japan

- Ginza×CSR・CSV Vol.32 ITOYA

- Ginza×CSR・CSV Vol.31 UNIQLO Ginza Store

- Ginza×CSR・CSV Vol.30 GINZA SIX Retail Management

- Ginza×CSR・CSV Vol.29 Ginza Kimuraya

- Ginza×CSR・CSV Vol.28 Lond

- Ginza×CSR・CSV Vol.27 cafe 634

- Ginza×CSR・CSV Vol.26 Ginza Cave Fujiki

- Ginza×CSR・CSV Vol.25 TBM

- Ginza×CSR・CSV Vol.24 Ginza West

- Ginza×CSR・CSV Vol.23 Ginza Sayegusa

- Ginza×CSR・CSV Vol.22 Ginza Tomato

- Ginza×CSR・CSV Vol.21 Kuipo Co., Ltd.

- Ginza×CSR・CSV Vol.20 Seiko Holdings

- Ginza×CSR・CSV Vol.19 SAPPORO LION

- Ginza×CSR・CSV Vol.18 Ginza Grand Hotel

- Ginza×CSR・CSV Vol.17 Isetan Mitsukoshi LTD Mitsukoshi Ginza Store

- Ginza×CSR・CSV Vol.16 Ginza Social Film Festival

- Ginza×CSR・CSV Vol.15 Yarakasukan

- Ginza×CSR・CSV Vol.14 Hakutsuru

- Ginza×CSR・CSV Vol.13 Swan

- Ginza×CSR・CSV Vol.12 Ginza Tanagokoro

- Ginza×CSR・CSV Vol.11 Mikimoto

- Ginza×CSR・CSV Vol.10 Novarese

- Ginza×CSR・CSV Vol.9 Sony Building

- Ginza×CSR・CSV Vol.8 Pola Orbis Holdings

- Ginza×CSR・CSV Vol.7 Ricoh

- Ginza×CSR・CSV Vol.6 Chuetsu Pulp & Paper Co.

- Ginza×CSR・CSV Vol.5 ALBION

- Ginza×CSR・CSV Vol.4 Bunshodo

- Ginza×CSR・CSV Vol.3 Recruit Holdings

- Ginza×CSR・CSV Vol.2 Specified Non-Profit Organization Ginza Honey Bee Project

- Ginza×CSR・CSV Vol.1 Shiseido